Translate:

Welcome

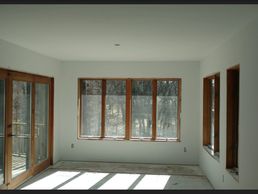

Here we will discuss a few things that everyone should know before having a drywall project take place. Being prepared &knowing what to expect will make your project go much more smoothly

The Stages of Drywalling

Drywall Hanging

Each sheet of drywall should be glued and screwed to the studs or joists. Starting with the ceiling &then the walls. Moisture Resistant Drywall (aka MRB or Green Board) should be used in bathrooms or in any other high moisture area. The fewer seams the better, & make sure the seams are tight together to ensure easier finishing & less chance of cracking.

Drywall Finishing

First, all of the seams must be coated with a glue based drywall compound and Drywall seam tape. Then each seam is coated 3 more times with a topping Mud (Drywall Compound). The outside corners are wrapped with a metal or plastic bead before being mudded.

Sanding & Priming

After the final appication of mud, it takes about 24-48 hours for the mud to dry enough to sand. Sanding takes out and rough lines or edges that will show up later. Once the drywall is sanded, its time to seal the drywall with a coat of PVA Primer which will get the new drywall ready for painting.

Process Broken Down

Drywall Hanging

Corner Bead & Moldings

Drywall Hanging

First the ceiling or Lid is hung. We recommend applying Adhesive to each joist, rafter or stud, & then screwing the drywall sheet perpendicular to the framing. For ceilings we screw along each rafter or joist along the beveled edge of the drywall as well as adding in 3 additional screws evenly spaced in the middle of the sheet (referred to as the field). On walls, we usually only use 2 screws in the field. The drywall Adhesive will help provide a firm hold along the entire stud. After the lid is hung, we hang the walls. The fewer seams the better. Also, you never want a seam above a door or window if you can help it. Avoiding seams in those areas will help reduce stress cracks in the future.

Taping

Corner Bead & Moldings

Drywall Hanging

Coming soon

Corner Bead & Moldings

Corner Bead & Moldings

Corner Bead & Moldings

Coming soon

Coating & Finishing

Coating & Finishing

Corner Bead & Moldings

Coming soon

Sanding & Textures

Coating & Finishing

Sanding & Textures

Coming soon

Priming & Sealing

Coating & Finishing

Sanding & Textures

Coming soon

Copyright © 2018 Silver Forest Contracting - All Rights Reserved.

Powered by GoDaddy